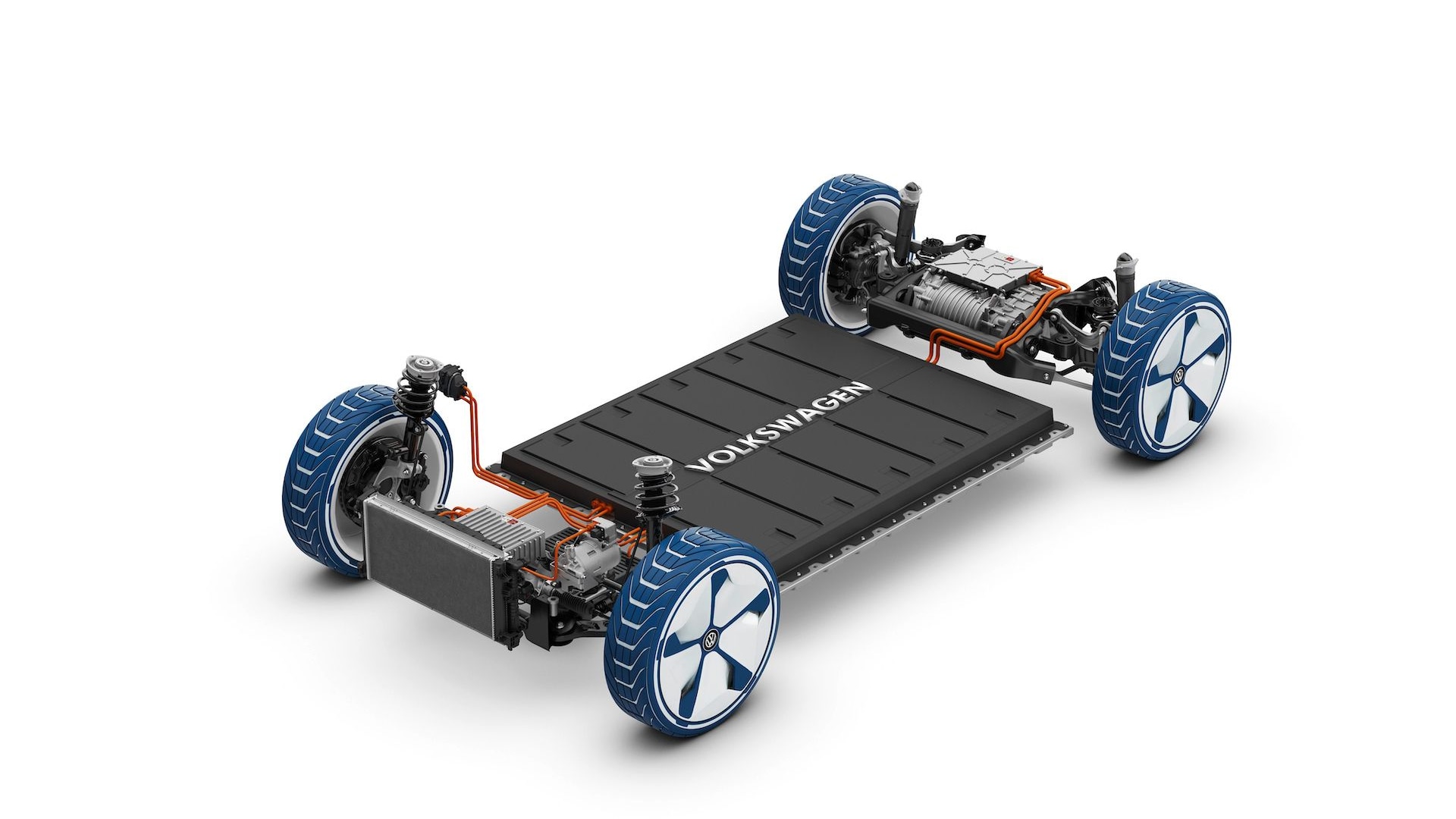

Electric Vehicle Battery Pack Contactors For Cars. There are two main types of contactors: Electrifying trucks for long hauls.

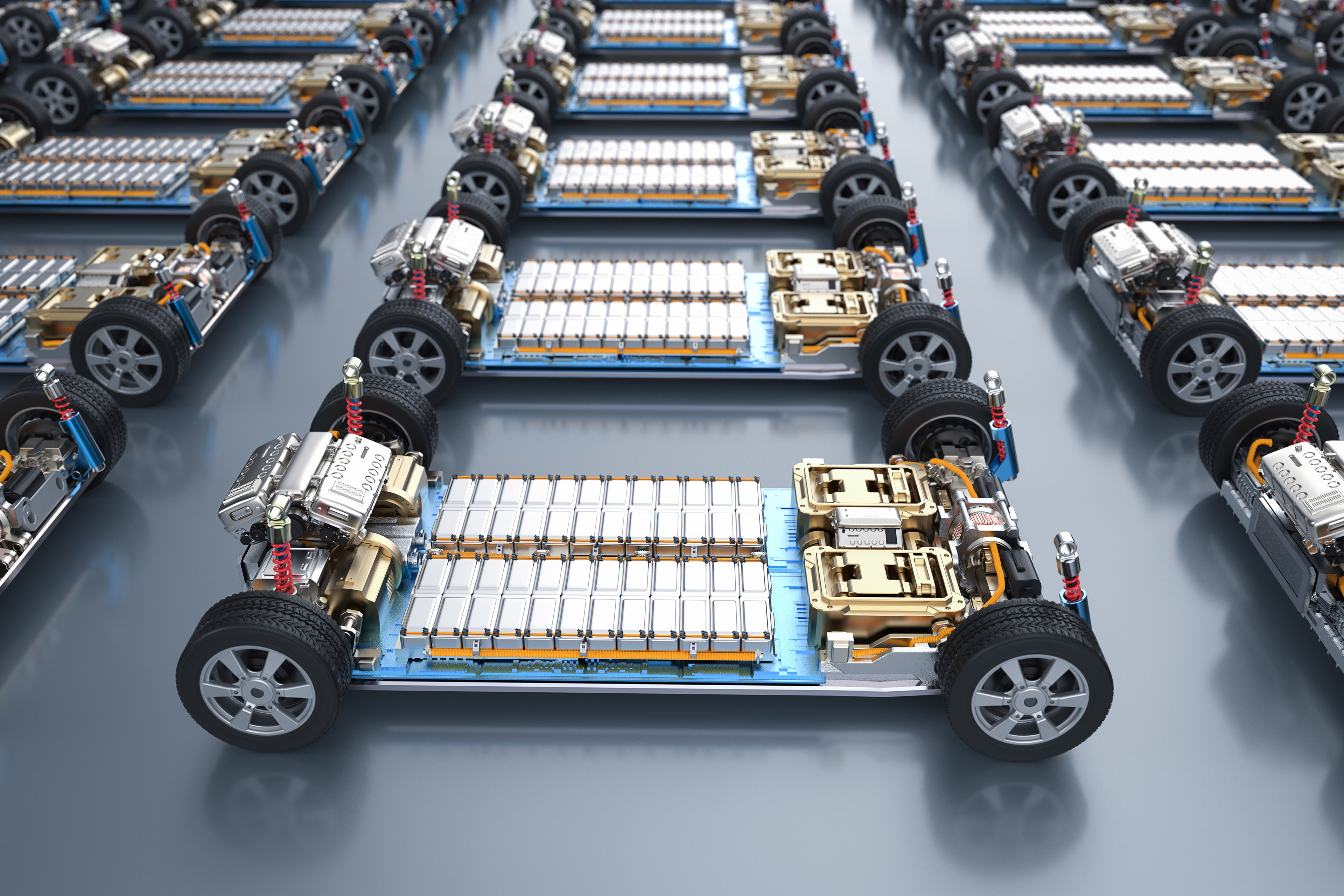

Thus, you have been using these terms interchangeably, not knowing that they refer to different elements in an ev battery. Ev cells may be small cylindrical cells, like a aa or aaa cell, of.

Each Battery Pack Has An Energy Content Of Around 90Kwh And So Six In Parallel, Like You Might Find In A Volvo Truck, Has A Total Energy Content Of 540Kwh.

Contactor selection is an iterative process that includes consideration of system specifications as well as failure scenarios.

Up To Several Dozen Modules Can Reside Within A Battery Pack, Which Is The Complete Ev Battery.

One each in the positive terminal, negative terminal, and precharge circuits.

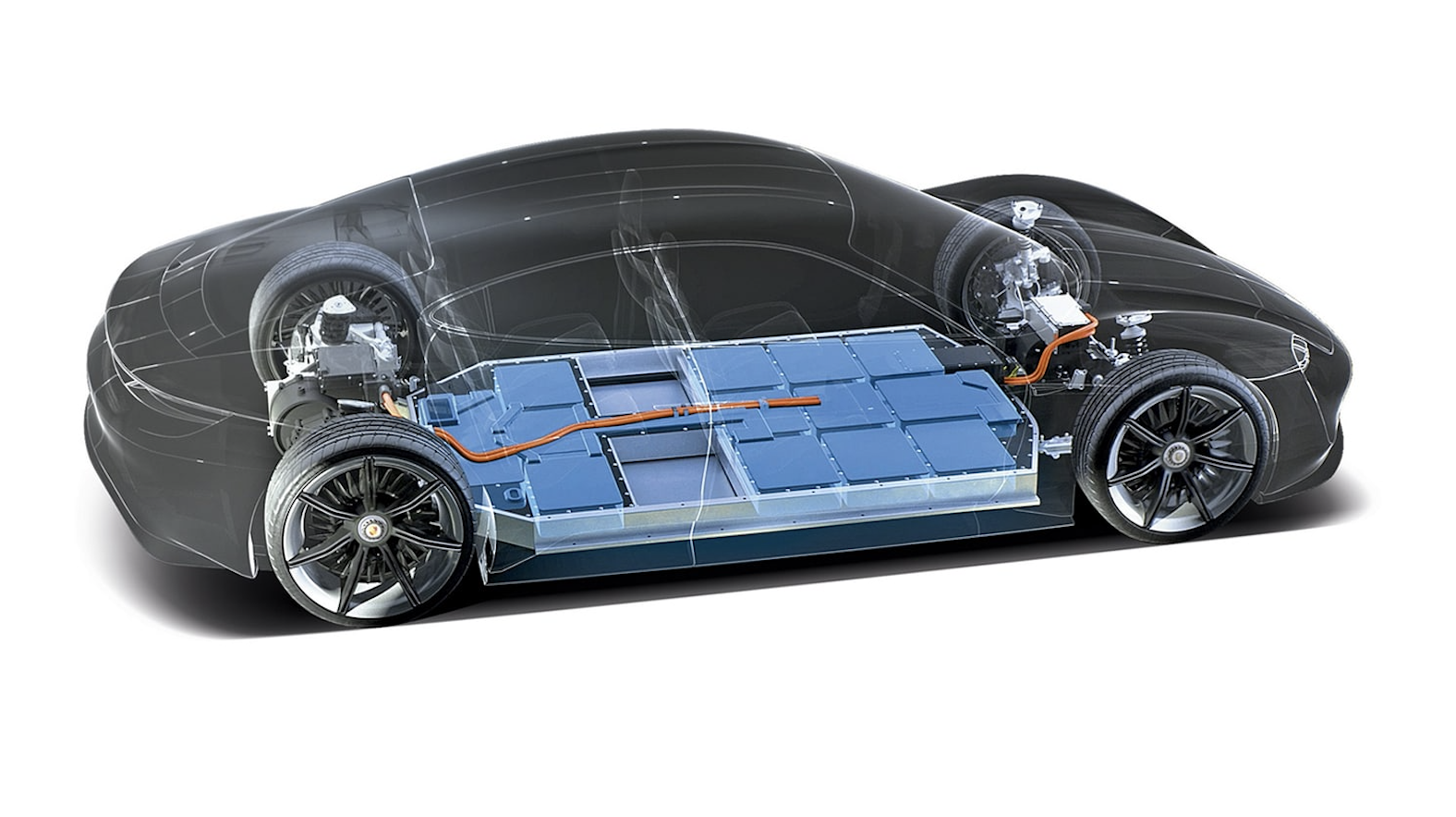

The Battery Must Be Designed To Satisfy The.

Images References :

Source: www.hotsoninternational.com

Source: www.hotsoninternational.com

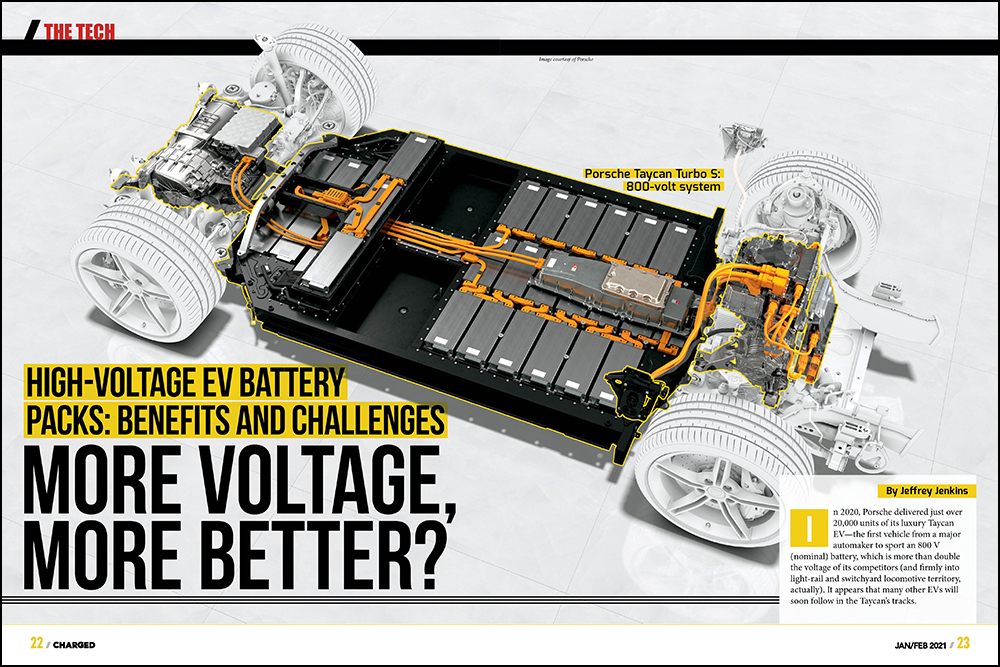

All You Want to Know About Electric Vehicle Battery High voltage DC, Appropriate for the majority of hv ev applications, dc. The battery management system is an electronic system that controls and protects a rechargeable battery to guarantee its best performance, longevity, and safety.

Source: mypoisonedapple.blogspot.com

Source: mypoisonedapple.blogspot.com

Electric Vehicle Battery Pack Battery Pack Kwh Built System Ev 144v 96v, The battery and the inverter are. Electrifying trucks for long hauls.

Source: us.misumi-ec.com

Source: us.misumi-ec.com

How Electric Vehicle Battery Packs are Manufactured MISUMI Mech Lab Blog, The battery and the inverter are. Up to several dozen modules can reside within a battery pack, which is the complete ev battery.

Source: www.ey.com

Source: www.ey.com

The next big thing in electric vehicle manufacturing EY US, Here's a look at the heart of every ev: Electric vehicle design is a complex concept.

Source: chargedevs.com

Source: chargedevs.com

Charged EVs Highvoltage EV battery packs benefits and challenges, Here's a look at the heart of every ev: In this review paper, all the battery specifications have been compared based on the data.

Source: fnnewsonline.com

Source: fnnewsonline.com

All About Electric Car Batteries, Consequently, contactors intended for use in evs usually advise ending precharge when the voltage differential is around 5 v so. As yet, there's no definite launch date, but the schedule for earlier artemis missions suggests.

Source: us.misumi-ec.com

Source: us.misumi-ec.com

How Electric Vehicle Battery Packs are Manufactured MISUMI Mech Lab Blog, Evc 175 main contactor based on the proven. Up to several dozen modules can reside within a battery pack, which is the complete ev battery.

Source: www.carlithiumbattery.com

Source: www.carlithiumbattery.com

108V 325Ah Electric Car Battery IP66 Protection Level ,Fast Charging ,Rohs, Te's compact evc 135 contactors provide fast, reliable switching and custom connections for hybrid and electric vehicles. As yet, there's no definite launch date, but the schedule for earlier artemis missions suggests.

Source: ar.inspiredpencil.com

Source: ar.inspiredpencil.com

Electric Car Battery Pack, In this review paper, all the battery specifications have been compared based on the data. Appropriate for the majority of hv ev applications, dc.

Source: www.solutions.covestro.com

Source: www.solutions.covestro.com

EV battery pack design Covestro AG, Voltage (hv) dc contactors or relays to meet a wide range of electric vehicle (ev) application requirements. The battery and the inverter are.

Normally Open (No) And Normally Closed (Nc).

Many electric vehicles (evs) use three contactors:

With This Increased Capability, Comes Greater Operating Currents, Fault Currents, And Voltage Isolation Requirements, All Of Which Drive The Need For Improved.

The battery management system is an electronic system that controls and protects a rechargeable battery to guarantee its best performance, longevity, and safety.